Robot Unties Knotted Cables But Cant Pick Them Up

Robot unties knotted cables but cant pick them up off the floor – Robot Unties Knotted Cables But Can’t Pick Them Up – it sounds like a scene from a science fiction movie, right? Imagine a robot that can deftly untangle a mess of cables, but then struggles to pick up the loose ends.

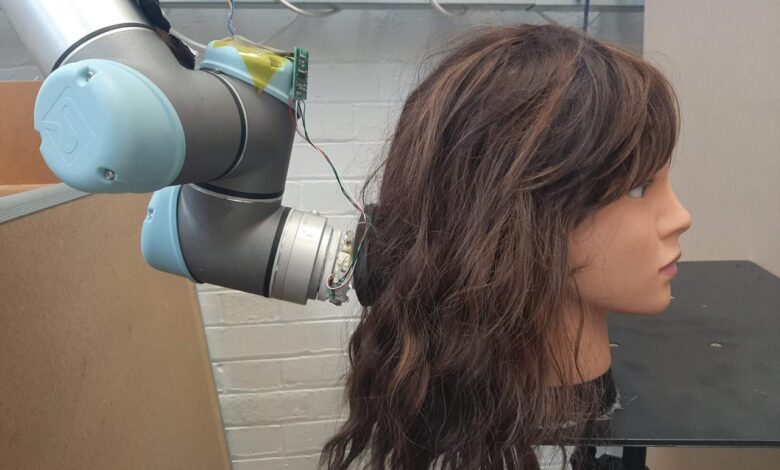

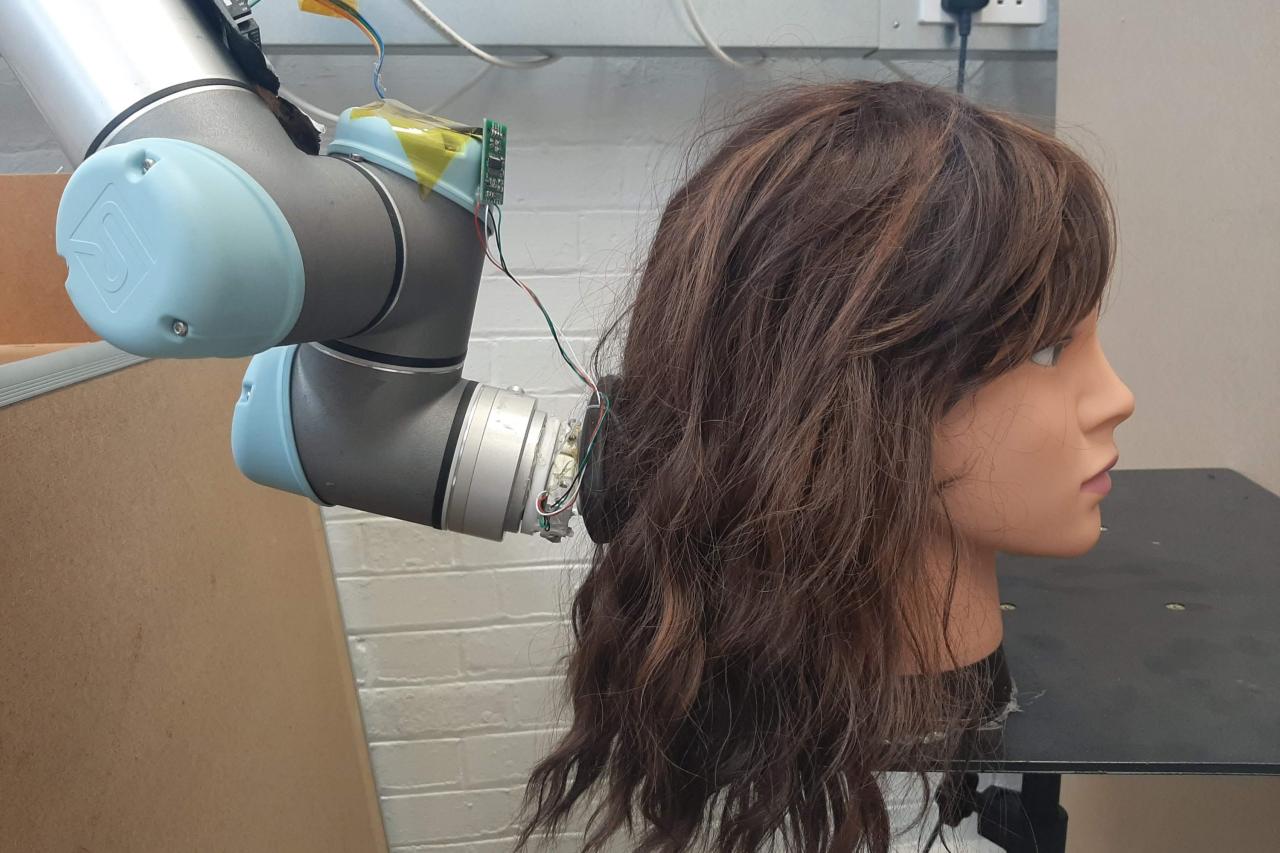

This seemingly simple task highlights the complex challenges of designing robots that can manipulate objects with the same dexterity as humans. While robots are increasingly adept at performing repetitive tasks, handling delicate objects like cables still poses a significant challenge.

This gap between human and robotic dexterity stems from the limitations of current robotic manipulation techniques, particularly when it comes to grasping and lifting objects with irregular shapes and textures.

The ability to untangle knots is a testament to the complex interplay of dexterity, perception, and control that is required for successful manipulation. Current robots lack the fine motor skills and tactile feedback necessary to navigate the intricate paths of knotted cables.

Researchers are actively exploring solutions, such as advanced sensor systems, soft robotics, and AI algorithms, to bridge this gap. The potential applications of such robots are vast, ranging from automated cable management in factories and data centers to assisting with delicate tasks in healthcare and surgery.

However, there are also ethical considerations to be addressed, such as the impact on employment and the potential risks associated with relying on robots for critical tasks.

The Role of Artificial Intelligence: Robot Unties Knotted Cables But Cant Pick Them Up Off The Floor

The ability to untangle knotted cables is a challenging task for robots due to the complex geometry and varying material properties involved. However, the field of artificial intelligence (AI) offers promising solutions to empower robots with the intelligence and adaptability needed to overcome these challenges.

AI algorithms, particularly those based on machine learning, can be instrumental in enabling robots to learn and adapt to complex tasks like untying knots.

Machine Learning for Cable Manipulation

Machine learning can be used to train robots to identify and manipulate cables effectively. This involves training algorithms on large datasets of cable configurations, knot types, and successful manipulation techniques. By analyzing these data, the algorithms learn to recognize patterns and develop strategies for untying knots.

For example, a robot could be trained to identify different types of knots based on their visual features, such as the number of loops and the way they are intertwined. It could also learn to predict the optimal sequence of movements required to untangle a specific knot.

AI-Powered System for Cable Untangling

An AI-powered system for cable untangling would consist of several key components:* Vision System:A camera or sensor to capture images or data of the cable configuration.

Knot Detection Algorithm

An AI algorithm to identify and classify the types of knots present.

Manipulation Planning Algorithm

An AI algorithm to determine the optimal sequence of movements for untying the knots.

Robot Controller

A system to execute the planned movements using the robot’s actuators.This system would work by first capturing an image of the tangled cables. The knot detection algorithm would then analyze the image to identify and classify the knots. Based on this information, the manipulation planning algorithm would generate a sequence of movements for the robot to execute.

The robot controller would then translate these movements into commands for the robot’s actuators.

AI in Robotic Manipulation

AI is already being used in various robotic manipulation tasks, including:* Object Grasping:Robots are being trained to grasp objects of different shapes and sizes using machine learning techniques.

Assembly Tasks

AI algorithms are being used to plan and execute complex assembly processes, such as assembling electronic components.

Surgical Robotics

AI is playing an increasingly important role in surgical procedures, enabling robots to perform delicate and precise movements.

Comparison of AI Techniques for Object Manipulation

| AI Technique | Description | Suitability for Cable Handling ||—|—|—|| Supervised Learning | Training algorithms on labeled data to predict outputs based on inputs | Suitable for identifying knot types and predicting manipulation sequences || Reinforcement Learning | Training algorithms to learn optimal actions through trial and error | Suitable for developing strategies for untying knots based on feedback from the environment || Deep Learning | Using artificial neural networks to learn complex patterns from data | Suitable for analyzing cable configurations and predicting optimal manipulation approaches |

Future Directions

The limitations of current robotic manipulation technologies in handling delicate objects like cables present exciting opportunities for future advancements. The integration of emerging technologies like soft robotics and haptic feedback holds the potential to revolutionize robotic dexterity, paving the way for robots that can navigate complex environments and interact with objects with unprecedented precision.

The Potential of Soft Robotics, Robot unties knotted cables but cant pick them up off the floor

Soft robotics, a field that focuses on creating robots made from flexible and adaptable materials, offers a promising solution to the challenges of handling delicate objects. Unlike traditional rigid robots, soft robots can conform to the shape of their environment, making them ideal for navigating tight spaces and manipulating objects with varying shapes and sizes.

This adaptability allows soft robots to gently grasp and manipulate cables without causing damage, a feat that is difficult for rigid robots to achieve.

Soft robots can gently grasp and manipulate cables without causing damage, a feat that is difficult for rigid robots to achieve.

The Role of Haptic Feedback

Haptic feedback, which provides tactile sensations to the user, can significantly enhance robotic dexterity by providing robots with a sense of touch. By incorporating haptic feedback into robotic systems, we can enable robots to perceive the texture, shape, and force required to manipulate objects with greater precision.

This technology can be particularly valuable for tasks involving delicate objects like cables, where the robot needs to apply the appropriate amount of force to avoid damage.

Haptic feedback can enable robots to perceive the texture, shape, and force required to manipulate objects with greater precision.

Research Project: Robots for Cable Handling

A research project focusing on developing robots capable of handling delicate objects like cables could involve the following steps:

- Develop a soft robotic gripper that can gently grasp and manipulate cables without causing damage.

- Integrate haptic feedback into the robotic system to provide the robot with a sense of touch and enable it to perceive the forces involved in cable manipulation.

- Train the robot using machine learning algorithms to recognize and untangle knots in cables.

- Test the robot’s performance in real-world scenarios involving cable handling tasks.

Ethical Considerations and Potential Risks

The widespread use of robots for cable handling tasks raises ethical considerations and potential risks.

- Job displacement: The automation of cable handling tasks could lead to job displacement for human workers.

- Safety concerns: The use of robots in complex environments could pose safety risks to human workers.

- Privacy concerns: Robots equipped with sensors and cameras could raise privacy concerns.

Timeline for Robotic Cable Handling

Developing robots capable of untying knots and picking up cables will require significant advancements in robotic manipulation technology. Here is a possible timeline outlining potential milestones:

- 2025-2030:Development of soft robotic grippers with improved dexterity and haptic feedback systems.

- 2030-2035:Integration of machine learning algorithms for knot detection and untangling.

- 2035-2040:Deployment of robots for cable handling tasks in controlled environments, such as manufacturing facilities.

- 2040 onwards:Widespread adoption of robots for cable handling tasks in various industries, including telecommunications, construction, and aerospace.

It’s fascinating to watch a robot untangle a knot of cables. It’s like watching a magician work their magic, except instead of a disappearing rabbit, it’s a mess of wires. But the real magic would be if the robot could then pick those cables up off the floor! Maybe that’s a job for a different kind of robot, one that’s a bit more “hands-on.” Speaking of hands-on, one Eric reaps in Missouri as another Eric sows , a phrase that reminds me of the delicate balance between automation and human effort.

Anyway, back to the robot. It’s impressive how far they’ve come, but maybe someday we’ll have robots that can do both – untangle and pick up!

It’s fascinating how robots can solve complex tasks like untangling knotted cables, but still struggle with the simple act of picking them up from the floor. It reminds me of how Sir Ian McKellen, a true stage legend, felt ashamed and emotional after a recent stage fall, as reported on this blog.

Perhaps we can learn something from both these examples: sometimes, the most basic tasks can be the most challenging, and even the most experienced among us can experience moments of vulnerability.

It’s amazing how robots can untangle knotted cables, but it seems they still struggle with the simple task of picking them up off the floor. Maybe we should give them some lessons from the NHS, who are using drones to fly blood samples around London to avoid traffic in a new trial.

It’s a great example of how technology can be used to solve real-world problems, even if it’s not always perfect. Perhaps the robot could learn a thing or two from the drones, or maybe they can collaborate on a solution to the cable-picking problem.