Chipset Shortage Hits Chip Makers Intel and TSMC

Chipset shortage hits chip makers Intel and TSMC sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset. The global semiconductor industry is facing a severe chipset shortage, a crisis that has significantly impacted major players like Intel and TSMC.

This shortage, fueled by a confluence of factors, has disrupted supply chains, driven up prices, and forced companies to scramble for solutions.

The shortage has its roots in the pandemic, which led to increased demand for electronics and a surge in chip orders. Simultaneously, production was hampered by factory closures and disruptions in the supply of raw materials. The situation was further exacerbated by geopolitical tensions, including trade wars and sanctions, which further complicated the supply chain.

Chipset Shortage Impact

The global semiconductor shortage has had a profound impact on the technology industry, particularly on chip makers like Intel and TSMC. This shortage has disrupted supply chains, slowed down production, and led to higher prices for electronic devices.

Timeline of the Chipset Shortage

The chipset shortage has been a gradual process, with several key factors contributing to its escalation.

- Increased Demand:The COVID-19 pandemic fueled a surge in demand for electronic devices, as people relied heavily on technology for work, entertainment, and education. This surge in demand strained supply chains and exacerbated existing shortages.

- Supply Chain Disruptions:The pandemic also disrupted global supply chains, causing factory closures, transportation delays, and labor shortages. These disruptions hindered the production and distribution of semiconductors, further aggravating the shortage.

- Geopolitical Tensions:Trade tensions between the United States and China, as well as the ongoing conflict in Ukraine, have also contributed to the shortage. These tensions have disrupted the flow of raw materials and components needed for semiconductor production.

- Natural Disasters:Natural disasters, such as the earthquake in Japan in 2011 and the drought in Taiwan in 2021, have also impacted semiconductor production. These events have damaged manufacturing facilities and disrupted supply chains.

Impact on Intel and TSMC

Intel and TSMC, two of the world’s leading chip makers, have been significantly impacted by the chipset shortage.

- Reduced Production:Both Intel and TSMC have been forced to reduce their production output due to the shortage of key components. This has resulted in longer wait times for chips and increased prices for electronic devices.

- Increased Costs:The shortage has also driven up the cost of raw materials and manufacturing, leading to higher production costs for Intel and TSMC. These increased costs have been passed on to consumers in the form of higher prices for electronic devices.

- Competition for Resources:The shortage has created intense competition for scarce resources, forcing Intel and TSMC to prioritize their production efforts and allocate resources strategically. This has led to challenges in meeting the demands of their customers.

Data and Statistics

The severity of the chipset shortage can be illustrated by the following data and statistics:

- Global Semiconductor Revenue:The global semiconductor market reached a record high of $555.9 billion in 2021, according to the Semiconductor Industry Association (SIA). This growth was fueled by the surge in demand for electronic devices during the pandemic.

- Lead Times:The lead time for procuring semiconductors has increased significantly, with some chips taking up to 52 weeks to deliver. This extended lead time has disrupted production schedules and created uncertainty for manufacturers.

- Price Increases:The shortage has driven up the price of semiconductors, with some chips experiencing price increases of up to 30%. These price increases have been passed on to consumers, leading to higher prices for electronic devices.

Intel’s Response

Intel, as a leading semiconductor manufacturer, has been significantly impacted by the global chipset shortage. The company has implemented a range of strategies to address the shortage and mitigate its impact on its operations and revenue streams.

Production Adjustments and Partnerships

Intel has taken several steps to increase its production capacity and secure a more stable supply of chips. These include:

- Expanding Production Capacity:Intel has announced plans to invest billions of dollars in expanding its manufacturing facilities, including the construction of new fabs in the United States and Europe. This expansion aims to increase its production capacity and reduce its reliance on external foundries.

- Strategic Partnerships:Intel has formed partnerships with other companies in the semiconductor industry to access additional manufacturing capacity. These partnerships include collaborations with companies like TSMC, Samsung, and GlobalFoundries.

- Optimizing Production Processes:Intel has focused on optimizing its existing production processes to improve efficiency and increase output. This includes adopting new technologies and streamlining manufacturing workflows.

Impact on Intel’s Product Offerings and Revenue Streams

The chipset shortage has impacted Intel’s product offerings and revenue streams in several ways:

- Limited Product Availability:The shortage has led to limited availability of certain Intel products, particularly in the PC and server markets. This has impacted Intel’s ability to meet customer demand and has potentially led to lost sales.

- Increased Prices:The shortage has driven up prices for semiconductors, including Intel’s products. This has impacted Intel’s pricing strategy and has potentially reduced profit margins.

- Delayed Product Launches:The shortage has delayed the launch of some Intel products, impacting the company’s product roadmap and its ability to compete effectively in the market.

Challenges and Mitigation Strategies, Chipset shortage hits chip makers intel and tsmc

Intel faces several challenges due to the chipset shortage, including:

- Competition for Manufacturing Capacity:Intel is competing with other semiconductor manufacturers for access to limited manufacturing capacity, which can lead to higher production costs and delays.

- Supply Chain Disruptions:The shortage has caused disruptions in Intel’s supply chain, impacting the availability of raw materials and components needed for chip production.

- Increased Costs:The shortage has driven up costs for raw materials, manufacturing, and logistics, impacting Intel’s profitability.

Intel is mitigating these challenges by:

- Diversifying its Supply Chain:Intel is working to diversify its supply chain by sourcing components from multiple suppliers and regions. This reduces its dependence on any single supplier and improves its resilience to disruptions.

- Investing in Research and Development:Intel is investing heavily in research and development to develop new technologies and manufacturing processes that can improve its efficiency and reduce its reliance on external foundries.

- Building Strategic Partnerships:Intel is forging strategic partnerships with other companies in the semiconductor industry to access additional manufacturing capacity and technology.

TSMC’s Perspective

TSMC, the world’s largest semiconductor foundry, has been at the forefront of the global chipset shortage. The company’s approach to managing this challenge has been a combination of strategic production adjustments, supply chain diversification, and long-term investments. This strategy aims to mitigate the immediate impact of the shortage while simultaneously bolstering its position in the semiconductor industry for the future.

TSMC’s Production Capabilities and Supply Chain Strategies

TSMC’s production capabilities are crucial to its ability to navigate the chipset shortage. The company has invested heavily in advanced manufacturing technologies, enabling it to produce chips with smaller feature sizes and higher performance. This technological edge allows TSMC to produce more chips per wafer, increasing its overall production capacity.

Additionally, TSMC has implemented a multi-pronged approach to supply chain management. This includes diversifying its customer base, expanding its manufacturing facilities, and strengthening partnerships with key suppliers.

The global chip shortage has been a major headache for tech giants like Intel and TSMC, impacting everything from gaming consoles to smartphones. While we wait for the industry to catch up, why not take a break and dive into the world of sports with some engaging reads?

Check out this awesome list of 20 super sports books for kids of all ages for some fun and educational entertainment. Once you’ve finished reading, you can come back to the news about Intel and TSMC’s struggles with the chip shortage, but for now, enjoy the world of sports literature!

Impact of the Shortage on TSMC’s Operations

The chipset shortage has undoubtedly affected TSMC’s operations. The company has experienced increased demand for its products, leading to longer lead times and potential production delays. TSMC has responded by prioritizing orders from its most important customers, while also working to increase its production capacity.

Long-Term Implications for TSMC’s Market Position and Future Growth

The chipset shortage has highlighted the importance of semiconductor manufacturing and has accelerated investments in this sector. TSMC’s strong position in the industry has been further solidified due to its advanced manufacturing capabilities and commitment to innovation. This positions the company for continued growth in the long term, with increased demand for advanced chips driving further investment in its facilities and research and development.

The global chip shortage continues to impact giants like Intel and TSMC, with repercussions felt across industries. While these companies grapple with supply chain issues, the nation is also bracing for a different kind of shock – the first televised hearing of the January 6th Committee, set to reveal a “mountain of new evidence” according to recent reports.

Whether it’s a shortage of microchips or a shortage of truth, the coming weeks are sure to be eventful.

Industry-Wide Implications

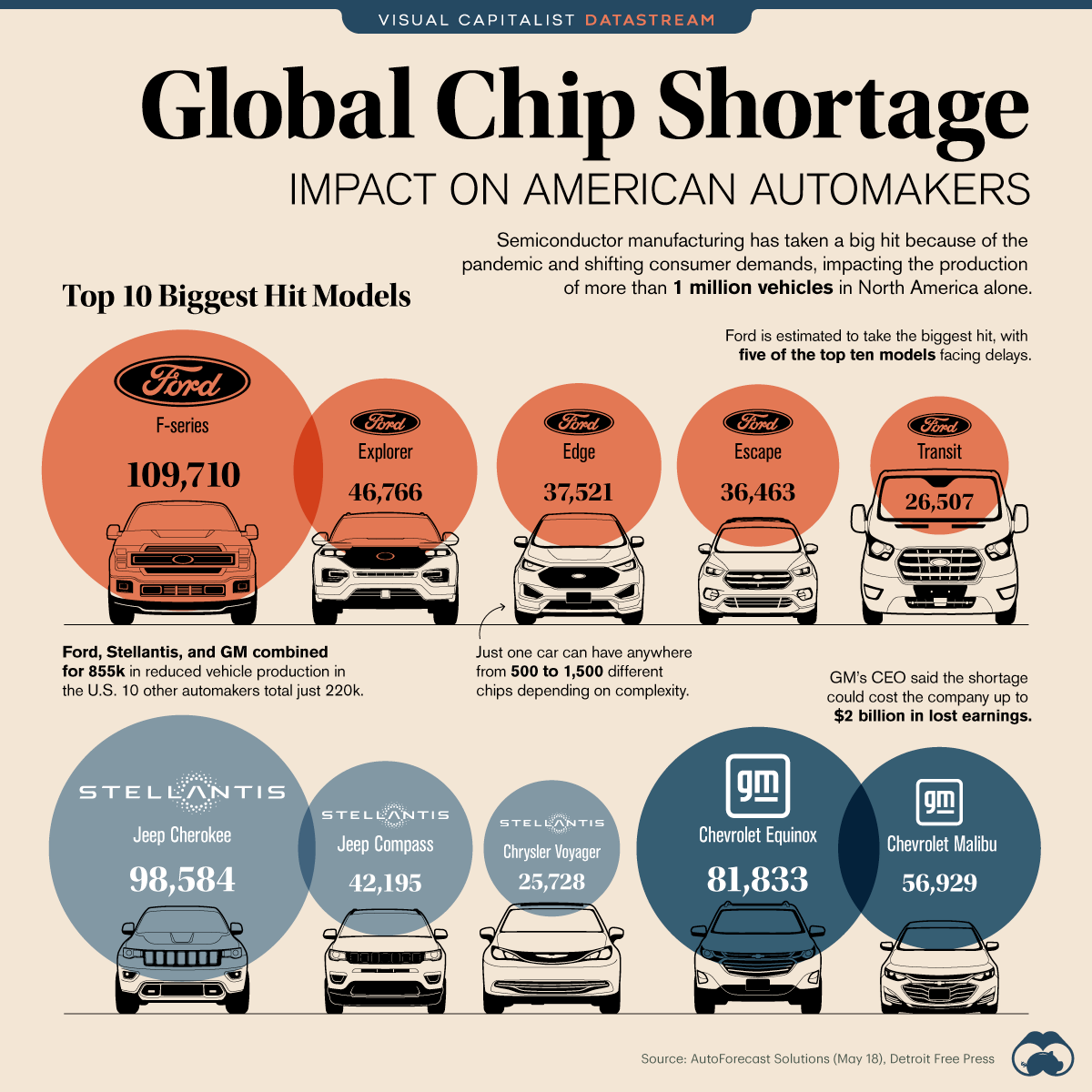

The global chipset shortage has rippled through various sectors, impacting production, pricing, and consumer access to essential technologies. The automotive, consumer electronics, and data center industries are among the most significantly affected, experiencing disruptions and adjustments in their operations.

Economic Consequences

The chipset shortage has had far-reaching economic consequences, leading to price increases, supply chain disruptions, and potential job losses. As demand for chips outstrips supply, manufacturers are forced to raise prices to compensate for increased production costs and limited availability.

This, in turn, leads to higher prices for consumers, impacting their purchasing power and potentially hindering economic growth. The shortage has also created significant disruptions in global supply chains. Companies are struggling to secure the components they need to manufacture their products, leading to production delays and inventory shortages.

This can have a domino effect, disrupting entire industries and affecting economic activity.

The chip shortage impacting Intel and TSMC is a serious issue, but it also highlights the need for businesses to adapt their marketing strategies. With privacy concerns growing, it’s more important than ever to focus on ethical data collection and personalized experiences.

Check out this article on how to do digital marketing in the age of privacy for some valuable insights. As the chip shortage continues, businesses need to be creative and flexible in their marketing approaches to stay ahead of the curve.

- For example, the automotive industry has been particularly hard-hit, with car manufacturers forced to cut production due to a lack of essential chips. This has resulted in longer waiting times for new cars, increased prices, and potential job losses in the sector.

- Similarly, the consumer electronics industry has seen price increases and reduced product availability. The shortage of chips has impacted the production of smartphones, laptops, and other devices, leading to higher prices and longer wait times for consumers.

Impact on Different Industries

The impact of the chipset shortage varies across different industries, with some sectors facing more severe challenges than others.

| Industry | Key Challenges | Potential Solutions |

|---|---|---|

| Automotive | Shortage of microcontrollers and other essential chips, leading to production cuts and longer waiting times for new cars. | Increased investment in domestic chip production, collaboration with chip manufacturers, and exploring alternative chip designs. |

| Consumer Electronics | Reduced availability of chips for smartphones, laptops, and other devices, leading to price increases and longer wait times for consumers. | Diversification of chip suppliers, prioritizing essential components, and exploring alternative chip designs. |

| Data Centers | Shortage of high-performance computing chips, impacting cloud computing services and data processing capabilities. | Investment in advanced chip manufacturing facilities, development of new chip architectures, and optimization of data center infrastructure. |

Potential Solutions and Future Outlook: Chipset Shortage Hits Chip Makers Intel And Tsmc

The global chip shortage has had a profound impact on various industries, highlighting the need for robust solutions to ensure a stable and resilient semiconductor supply chain. Addressing this challenge requires a multi-faceted approach, encompassing increased production capacity, exploration of alternative manufacturing methods, and strategic government intervention.

Increased Chip Production

Expanding chip production capacity is a crucial step in mitigating the shortage. This involves investing in new fabrication plants (fabs) and upgrading existing facilities to increase output.

- Government Incentives:Governments can incentivize chip manufacturers to build new fabs through tax breaks, subsidies, and grants. For example, the U.S. government has passed the CHIPS and Science Act, allocating $52 billion for domestic semiconductor production.

- Private Investment:Companies like Intel, Samsung, and TSMC are making significant investments in expanding their production capacity. Intel, for instance, announced plans to build two new fabs in Ohio, totaling $20 billion in investment.

- Collaboration:Collaboration between governments, chipmakers, and research institutions is essential for developing advanced technologies and fostering innovation in chip manufacturing.

Alternative Manufacturing Methods

Exploring alternative manufacturing methods can enhance chip production efficiency and address supply chain vulnerabilities.

- Advanced Packaging:This technique involves integrating multiple chips onto a single substrate, reducing the need for individual chips and increasing overall performance.

- 3D Chip Stacking:This method stacks multiple chips vertically, increasing chip density and performance while reducing the need for larger wafers.

- Advanced Materials:Utilizing new materials, such as gallium nitride (GaN) and silicon carbide (SiC), can enhance chip performance and efficiency.

Government Intervention

Government intervention can play a vital role in stabilizing the chip supply chain.

- Trade Policies:Governments can implement trade policies to promote domestic chip production and reduce reliance on foreign suppliers.

- Research and Development:Investing in research and development for advanced chip technologies can help drive innovation and improve chip manufacturing capabilities.

- Strategic Stockpiling:Governments can consider stockpiling essential chips to ensure availability during times of crisis.

Long-Term Outlook for the Chipset Market

The long-term outlook for the chipset market is characterized by continued growth driven by technological advancements and increasing demand.

- Artificial Intelligence (AI):The development of AI applications, such as autonomous vehicles and smart homes, will require advanced chips with high processing power.

- Internet of Things (IoT):The proliferation of connected devices will fuel demand for chips with low power consumption and wireless connectivity.

- Cloud Computing:The shift towards cloud computing will require high-performance chips to support data processing and storage.

Timeline for Resolving the Chip Shortage

Resolving the chip shortage is a complex process that will require a coordinated effort from industry stakeholders and governments.

- Short-Term (1-2 years):Increased production capacity from existing fabs, coupled with government incentives, will help alleviate the immediate shortage.

- Mid-Term (3-5 years):New fabs coming online and adoption of alternative manufacturing methods will contribute to a more stable chip supply.

- Long-Term (5+ years):Technological advancements in chip design and manufacturing will drive a more resilient and sustainable chip ecosystem.

Final Thoughts

The chipset shortage has brought to light the fragility of global supply chains and the interconnectedness of the tech industry. While the immediate impact is felt by consumers and businesses alike, the long-term implications are far-reaching. As companies navigate this turbulent landscape, innovation and collaboration are crucial to mitigating the effects of the shortage and building a more resilient and sustainable future for the semiconductor industry.