Billions in EV Deals: Cant Fix US Supply Chain Woes

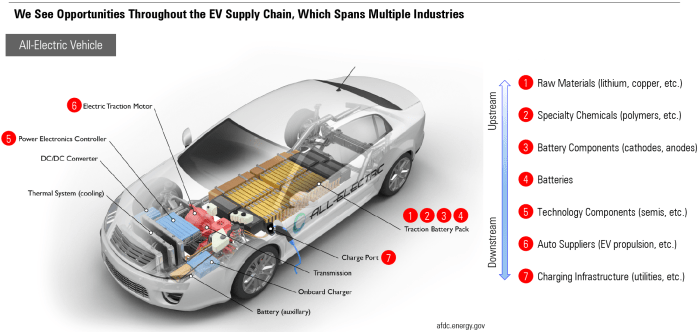

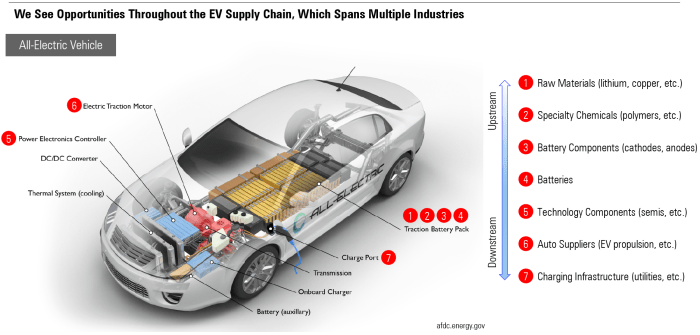

Analysis billions of dollars in deals cant smooth the us ev supply chain takes center stage, as the US grapples with a complex and fragile electric vehicle (EV) supply chain. Despite billions of dollars pouring into new factories and infrastructure, the road to EV dominance remains bumpy.

The global chip shortage, coupled with a reliance on foreign suppliers for key components, has left the US EV market vulnerable and struggling to keep pace with demand. While the government is pushing for domestic production, concerns remain about the ability to quickly scale up production and secure a reliable supply of critical materials.

This article dives into the challenges facing the US EV supply chain, examining the impact of recent investments and the critical factors that will determine the future of EV production in the US. We’ll explore the potential for the US to become a global leader in EV manufacturing and technology, while also considering the challenges and opportunities that lie ahead.

The Future of EV Production in the US: Analysis Billions Of Dollars In Deals Cant Smooth The Us Ev Supply Chain

The US is poised to become a global leader in EV production, driven by substantial investments and ambitious policy initiatives. The current landscape, marked by growing consumer demand and a commitment to reducing carbon emissions, presents a compelling opportunity for the US to establish itself as a dominant force in the EV market.

Impact of Investments and Policy Initiatives

The US government’s commitment to promoting EV adoption is evident in the substantial financial support provided to the industry. The Inflation Reduction Act (IRA), for example, offers significant tax credits for EV purchases and manufacturing, incentivizing both consumers and companies to embrace electric vehicles.

This legislation, coupled with other federal and state-level incentives, is fostering a favorable environment for EV production and innovation.The IRA’s impact on the EV supply chain is already being felt. Several major automakers have announced plans to expand their US manufacturing operations, spurred by the tax credits and the growing demand for EVs.

Tesla, for instance, is investing billions of dollars in a new Gigafactory in Texas, while Ford and General Motors are also significantly increasing their EV production capacity in the US.Beyond financial incentives, the US government is also taking steps to streamline the regulatory landscape for EV production.

This includes simplifying permitting processes for EV charging infrastructure and accelerating the development of battery recycling technologies. These initiatives aim to reduce the barriers to entry for EV companies and create a more robust ecosystem for EV production.

The US as a Global Leader in EV Manufacturing and Technology

The US has the potential to become a global leader in EV manufacturing and technology, leveraging its existing strengths in automotive engineering, research and development, and manufacturing capabilities. The nation’s strong infrastructure and skilled workforce provide a solid foundation for establishing a robust EV production sector.The US is already a leader in battery technology, with companies like Tesla and LG Energy Solution developing advanced battery chemistries and manufacturing processes.

This expertise, coupled with the government’s support for battery research and development, positions the US to play a crucial role in the global battery supply chain.The US is also making significant strides in EV charging infrastructure. The Biden administration has pledged to invest billions of dollars in building a nationwide network of EV charging stations, making it easier for consumers to adopt electric vehicles.

This infrastructure development, along with the increasing availability of EVs, is creating a positive feedback loop that is driving further growth in the EV market.

Challenges and Opportunities for US-based EV Companies, Analysis billions of dollars in deals cant smooth the us ev supply chain

While the US EV industry faces a number of challenges, it also presents a wealth of opportunities. The primary challenge lies in competing with established EV manufacturers in China and Europe, which have already built robust production and supply chains.The US must overcome the challenge of sourcing critical EV components, particularly batteries, which are currently heavily reliant on Chinese suppliers.

This necessitates the development of a domestic battery supply chain, which requires significant investment and coordination among government, industry, and research institutions.Another challenge is the need to address the cost of EV production, which remains higher than gasoline-powered vehicles. The US must leverage its technological innovation and manufacturing capabilities to reduce the cost of EVs and make them more accessible to a wider range of consumers.Despite these challenges, the US EV industry has significant opportunities for growth.

The growing global demand for EVs, coupled with the government’s commitment to supporting the industry, presents a compelling opportunity for US-based EV companies to capture a significant share of the market.The US can capitalize on its existing strengths in automotive engineering, research and development, and manufacturing to establish itself as a global leader in EV production.

By overcoming the challenges and leveraging the opportunities, the US EV industry is well-positioned to drive the future of sustainable transportation.

It’s fascinating how even billions of dollars in deals can’t seem to fix the US EV supply chain. It’s like trying to build a house with only half the bricks. And speaking of challenges, it’s worth remembering that complex geopolitical issues like why Islamism will continue to threaten liberal democracies in Europe can also disrupt global trade and economic progress.

Just like the EV supply chain, these issues require a multifaceted approach to address and ultimately find solutions. It’s a reminder that sometimes, the biggest obstacles are not just logistical, but ideological and political.

It’s fascinating how billions of dollars in deals can’t seem to fix the US EV supply chain. It’s like trying to build a house with only half the bricks. Meanwhile, we’re all trying to figure out what’s going on with the FBI raid on Donald Trump, and trying to make sense of the information that’s slowly being released.

What we know and what we don’t know about the FBI’s raid on Donald Trump is a story that’s still unfolding, just like the story of the EV supply chain. It’s a reminder that even with all the money and effort in the world, some problems are just really complex.

It’s fascinating how even billions of dollars in deals can’t seem to solve the US EV supply chain issues. It’s almost like a game of whack-a-mole, where addressing one bottleneck just creates another. Meanwhile, across the pond, London’s mayor is taking a different approach to infrastructure challenges, with plans to pedestrianize Oxford Street , one of the UK’s most famous shopping streets.

While this might not directly address the US EV supply chain, it highlights how different approaches can be taken to tackle complex issues. Perhaps there’s a lesson to be learned from London’s bold move when it comes to navigating the complexities of supply chains.