Can Indias Manufacturing Ambitions Bear Fruit?

Cnbcs inside india newsletter will indias lofty manufacturing ambitions bear fruit – Can India’s Manufacturing Ambitions Bear Fruit? sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset.

India’s aspirations to become a global manufacturing powerhouse are ambitious, but are they achievable? This exploration delves into the current state of India’s manufacturing sector, examining its strengths and weaknesses, and analyzing the factors driving its growth ambitions. We’ll investigate the challenges and opportunities that lie ahead, exploring the role of government policies, technological advancements, and the evolving global landscape in shaping India’s manufacturing future.

India’s Manufacturing Ambitions

India’s ambition to become a global manufacturing hub is a bold and ambitious goal, one that has the potential to transform the country’s economy and create millions of jobs. The “Make in India” initiative, launched in 2014, aims to attract foreign investment and promote domestic manufacturing by streamlining regulations, improving infrastructure, and fostering a more business-friendly environment.

The Current State of India’s Manufacturing Sector

India’s manufacturing sector is currently experiencing a period of significant growth, driven by increasing domestic demand, rising incomes, and a young and growing population. The sector accounts for about 26% of India’s GDP and employs over 100 million people. Despite the growth, the sector faces several challenges, including:* Lack of Infrastructure:Inadequate infrastructure, particularly in areas like power, transportation, and logistics, hampers manufacturing growth and increases production costs.

Skill Gap

A shortage of skilled labor, particularly in technical and managerial roles, limits the sector’s ability to compete globally.

Bureaucracy and Regulations

CNBC’s Inside India newsletter explores the question of whether India’s ambitious manufacturing goals will be realized. While it’s a fascinating topic, it’s hard not to be distracted by the news coming out of the UK, where households are being urged to stockpile cash and medicine this week.

The contrast between India’s long-term vision and the UK’s immediate anxieties highlights the different challenges facing economies around the world.

Complex and cumbersome regulations, including land acquisition and environmental clearances, often create roadblocks for businesses.

Access to Finance

Small and medium-sized enterprises (SMEs) often struggle to access affordable financing, limiting their ability to expand and invest in new technologies.

Competition

India faces intense competition from other emerging economies, particularly China, which has established itself as a global manufacturing powerhouse.

Factors Driving India’s Ambition

Several factors are driving India’s ambition to become a global manufacturing hub:* Growing Domestic Demand:India’s rapidly growing population and rising middle class are creating a large and expanding domestic market for manufactured goods.

Favorable Demographics

India has a young and growing population, with a large pool of skilled and semi-skilled labor, which is a key advantage in attracting manufacturing investments.

Government Initiatives

The government’s “Make in India” initiative has significantly boosted investor confidence and created a more conducive environment for manufacturing.

Cost Advantage

CNBC’s “Inside India” newsletter delves into whether India’s grand manufacturing goals will come to fruition. The article highlights the challenges and opportunities, mirroring the media’s battle cry – a constant push for progress and accountability – in holding the government accountable for its ambitious plans.

Ultimately, the success of India’s manufacturing ambitions hinges on overcoming these challenges and realizing its potential.

India offers a cost advantage compared to many developed economies, particularly in labor and raw materials, making it an attractive destination for manufacturing.

Technological Advancements

Advancements in technology, such as automation and robotics, are creating opportunities for India to leapfrog traditional manufacturing models and adopt more efficient and cost-effective production methods.

Comparing India’s Manufacturing Performance with Other Emerging Economies

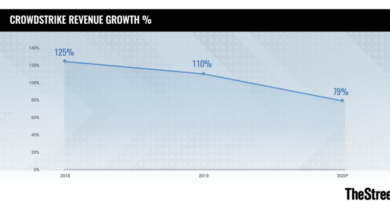

India’s manufacturing sector is growing rapidly, but it still lags behind other emerging economies, particularly China. China’s manufacturing sector is significantly larger and more sophisticated, with a well-developed infrastructure, skilled workforce, and access to global supply chains. However, India has a number of advantages, including a large and growing domestic market, a young and skilled workforce, and a government that is committed to promoting manufacturing.

Key Sectors Targeted for Growth under the ‘Make in India’ Initiative

The “Make in India” initiative has identified several key sectors for growth, including:* Automotive:India is aiming to become a global hub for automotive manufacturing, with a focus on electric vehicles and components.

Electronics

The government is encouraging domestic production of electronic goods, including smartphones, computers, and appliances.

Pharmaceuticals

India is a major player in the global pharmaceutical industry, and the government is supporting the growth of the sector through initiatives like the “Pharma Vision 2020” program.

CNBC’s “Inside India” newsletter delves into the ambitious “Make in India” program, questioning whether India’s manufacturing goals will be realized. While the focus is on economic development, it’s interesting to see how history often repeats itself. For instance, the current investigation into the 9/11 attacks, which could potentially subpoena Oval Office files, 911 commission could subpoena oval office files , reveals a similar drive for accountability, albeit in a different context.

Returning to India’s manufacturing ambitions, the newsletter examines the challenges and opportunities, providing insights into the country’s economic future.

Textiles and Apparel

India is a major exporter of textiles and apparel, and the government is working to improve the competitiveness of the sector through initiatives like the “Textile Policy 2020.”

Renewable Energy

India is aggressively pursuing renewable energy sources, such as solar and wind power, and the government is promoting domestic manufacturing of renewable energy equipment.

Challenges and Opportunities in India’s Manufacturing Growth

India’s ambition to become a global manufacturing powerhouse is driven by its vast population, a growing middle class, and a young and increasingly skilled workforce. However, the journey to achieve this goal is fraught with challenges.

Infrastructure Bottlenecks

Infrastructure plays a crucial role in supporting manufacturing growth. India faces significant infrastructure challenges, including inadequate power supply, inefficient logistics, and underdeveloped transportation networks. These bottlenecks increase production costs, hinder timely delivery of goods, and limit the ability of manufacturers to scale up operations.

For example, unreliable power supply can lead to production disruptions and increase energy costs, making Indian manufacturing less competitive.

Skilled Labor Shortages

India’s manufacturing sector faces a shortage of skilled labor, particularly in technical and specialized roles. The education system needs to be aligned with the evolving needs of the manufacturing industry, providing graduates with the necessary skills and training. The government is taking steps to address this challenge through initiatives like Skill India, which aims to train millions of young people in various skills, including those required for manufacturing.

Regulatory Hurdles

Complex and cumbersome regulations can create hurdles for manufacturers, leading to delays and increased costs. Streamlining regulations and creating a more business-friendly environment are essential to attract investments and foster growth. The government has taken steps to simplify regulations and promote ease of doing business in India, but more needs to be done to address the concerns of manufacturers.

Opportunities from Reshoring and Nearshoring

The global landscape is shifting towards reshoring and nearshoring, with companies looking to bring production closer to their markets or source goods from nearby locations. This presents a significant opportunity for India to attract investments and boost its manufacturing sector.

India’s large domestic market, growing middle class, and favorable cost structure make it an attractive destination for companies looking to reshore or nearshore their operations.

Role of Technology and Automation

Technology and automation are crucial for enhancing India’s manufacturing competitiveness. Adopting advanced technologies, such as robotics, artificial intelligence, and Industry 4.0 solutions, can improve efficiency, productivity, and quality, while reducing labor costs. However, India needs to invest in infrastructure, skills development, and technology adoption to fully leverage the benefits of automation.

Examples of Successful Indian Manufacturing Companies

Despite the challenges, several Indian manufacturing companies have achieved significant growth by overcoming obstacles and adapting to changing market conditions. For example, Tata Motors, one of India’s largest automobile manufacturers, has successfully expanded its global presence by focusing on innovation, quality, and cost competitiveness.

Similarly, Reliance Industries, a leading conglomerate, has made significant investments in manufacturing, particularly in the petrochemicals and textiles sectors, contributing to India’s economic growth.

The Role of Government Policies and Initiatives: Cnbcs Inside India Newsletter Will Indias Lofty Manufacturing Ambitions Bear Fruit

India’s ambitious manufacturing growth targets are not solely reliant on market forces. The government plays a crucial role in shaping the landscape, implementing policies and initiatives designed to accelerate growth and attract investment.

Government Policies and Initiatives for Manufacturing Growth

The Indian government has introduced a range of policies and initiatives to bolster the manufacturing sector. These include:

- Make in India Program: Launched in 2014, the Make in India program aims to position India as a global manufacturing hub. It focuses on attracting foreign investment, simplifying regulations, improving infrastructure, and promoting skill development. The program highlights 25 key sectors, including automobiles, electronics, pharmaceuticals, and textiles, emphasizing their potential for growth and job creation.

- Production Linked Incentive (PLI) Schemes: These schemes offer financial incentives to domestic manufacturers based on their production output. They target specific sectors, including mobile phones, electronics, automobiles, and pharmaceuticals. The PLI schemes aim to promote domestic production, boost exports, and create employment opportunities. The government has allocated billions of dollars to these schemes, demonstrating its commitment to incentivizing domestic manufacturing.

- Tax Incentives: The government offers various tax incentives to encourage manufacturing activities. These include accelerated depreciation on plant and machinery, tax holidays for new manufacturing units, and lower tax rates for certain sectors. These incentives aim to reduce the cost of production and make India more attractive for manufacturers.

Effectiveness of Government Policies in Attracting Investment and Boosting Production

The effectiveness of these policies in attracting foreign investment and boosting domestic production is evident in the growth of the manufacturing sector in recent years. India’s manufacturing sector has witnessed a significant increase in foreign direct investment (FDI) and domestic production, particularly in sectors targeted by the Make in India program and PLI schemes.

For example, the mobile phone manufacturing sector has seen a substantial increase in domestic production, with India becoming a global hub for mobile phone exports.

Impact of Government Policies on Ease of Doing Business

Government policies have also had a positive impact on the ease of doing business in India’s manufacturing sector. Initiatives like the Goods and Services Tax (GST) have simplified the tax regime and reduced compliance costs. Streamlining regulatory processes, improving infrastructure, and promoting digitalization have made it easier for businesses to operate in India.

The World Bank’s “Ease of Doing Business” rankings have seen India’s position improve significantly in recent years, reflecting the positive impact of government reforms.

Comparison of Government Initiatives, Cnbcs inside india newsletter will indias lofty manufacturing ambitions bear fruit

| Initiative | Objective ||—|—|| Make in India Program | Attract foreign investment, simplify regulations, improve infrastructure, promote skill development, and position India as a global manufacturing hub. || Production Linked Incentive (PLI) Schemes | Promote domestic production, boost exports, and create employment opportunities in targeted sectors.

|| Tax Incentives | Reduce the cost of production and make India more attractive for manufacturers. |

The Future of Manufacturing in India

India’s manufacturing sector is poised for significant growth in the coming years, driven by a confluence of factors including government initiatives, a burgeoning domestic market, and the increasing adoption of technology. The future of manufacturing in India is bright, with several key trends shaping the landscape.

The Impact of Emerging Technologies

Emerging technologies, such as artificial intelligence (AI) and robotics, are poised to revolutionize India’s manufacturing sector. AI can be used to optimize production processes, predict demand, and improve quality control. Robotics can automate repetitive tasks, freeing up human workers for more skilled roles.

The adoption of these technologies can enhance efficiency, productivity, and competitiveness. For instance, companies like Tata Motors and Mahindra & Mahindra are already using AI and robotics to improve their manufacturing processes.