Biden Invokes Defense Production Act for Baby Formula Ingredients

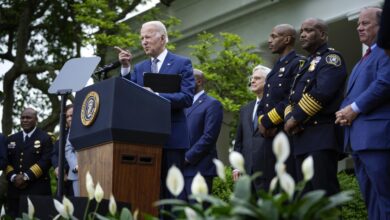

Biden invokes defense production act to require manufacture of baby formula ingredients – Biden Invokes Defense Production Act for Baby Formula Ingredients, a move that highlights the severity of the ongoing baby formula shortage and the government’s commitment to addressing this critical issue. The Defense Production Act, typically used in times of national emergency, empowers the President to direct companies to prioritize the production of essential goods.

This unprecedented action reflects the urgent need to increase the supply of baby formula and alleviate the anxieties of parents struggling to find it for their infants.

The shortage, triggered by a combination of factors including a major recall, supply chain disruptions, and formula manufacturing challenges, has left many families desperate. The Defense Production Act aims to address these challenges by prioritizing the production of key ingredients needed for baby formula.

This intervention will require manufacturers to ramp up production, potentially leading to a more stable supply of formula in the coming months.

The Defense Production Act and Baby Formula Shortage

The Defense Production Act (DPA) is a powerful tool that the U.S. government can use to address national emergencies. It was invoked by President Biden in May 2022 to address the critical baby formula shortage that was plaguing the nation.

This decision sparked debate and raised questions about the appropriate use of this act.

The Defense Production Act: A Tool for National Emergencies

The Defense Production Act, enacted in 1950, grants the President broad authority to direct private companies to prioritize the production of essential goods and services for national defense. The act has been invoked numerous times throughout history, often in response to wartime needs or other critical situations.

- During the Korean War, the DPA was used to expand the production of steel, aluminum, and other materials crucial for the war effort.

- In the 1970s, the act was employed to address the energy crisis by encouraging the production of alternative fuels.

- Following the 9/11 attacks, the DPA was invoked to increase the production of security equipment and medical supplies.

The Baby Formula Shortage: A Unique Application of the DPA

The baby formula shortage in 2022 was a complex crisis stemming from a confluence of factors:

- The closure of a major manufacturing plant due to safety concerns.

- Supply chain disruptions exacerbated by the COVID-19 pandemic.

- A surge in demand for baby formula, particularly for specialized formulas.

The shortage had a devastating impact on families across the country, leaving many parents struggling to find adequate nourishment for their infants. This unprecedented situation led to the invocation of the DPA to address the crisis.

The DPA and the Baby Formula Shortage: A Comparison to Historical Uses

While the DPA has traditionally been used to address national security concerns, its application to the baby formula shortage highlights its potential for addressing other critical domestic needs.

“The DPA is a powerful tool that can be used to address a wide range of national emergencies, from wartime production to natural disasters,” said a senior government official.

The Biden administration’s invocation of the Defense Production Act to ramp up baby formula production highlights the importance of addressing critical needs, and it reminds us that even amidst such urgent situations, we must prioritize the well-being of those who are most vulnerable.

Similarly, the initiative by Ripple Effects to offer access to its Educator Ally program recognizes the immense stress and emotional toll that teachers face, demonstrating a commitment to supporting their mental health and overall well-being. Just as the government is taking action to ensure access to essential infant nutrition, we must continue to prioritize the needs of those who are crucial to the development of our future generations.

The invocation of the DPA in this case differs from its historical uses in several ways:

- It was the first time the act was used to address a domestic shortage of a non-defense-related product.

- The focus was on increasing the production of a specific product, rather than a broad range of goods.

- The act was invoked to address a temporary crisis, rather than a long-term need.

Impact on Baby Formula Supply Chain

The Defense Production Act (DPA) is a powerful tool that allows the President to prioritize the production of essential goods during times of national emergency. In the context of the baby formula shortage, the DPA aims to address key bottlenecks in the supply chain and expedite the production of crucial ingredients.

It’s pretty amazing to see the government stepping in to address the baby formula shortage by invoking the Defense Production Act. It’s a reminder that even in times of crisis, there are ways to find solutions. And speaking of solutions, if you’re in a tough situation like a job share that’s not working out, there are resources available too! Check out this article from We Are Teachers on how to handle a job share that’s not working: ask weareteachers help i dont want to job share anymore.

The government’s actions on the baby formula shortage show that we can overcome even the most difficult challenges, and I hope that same spirit of problem-solving will help families find solutions to other tough situations.

Bottlenecks in the Baby Formula Supply Chain

The baby formula shortage has been caused by a complex interplay of factors, including:

- Recalls and Plant Closures:The recall of contaminated formula by Abbott Nutrition in February 2022 led to the closure of its largest manufacturing facility in Michigan, significantly reducing the supply of formula. The subsequent closure of other facilities due to safety concerns further exacerbated the shortage.

- Supply Chain Disruptions:The COVID-19 pandemic disrupted global supply chains, impacting the availability of raw materials and packaging components necessary for formula production.

- Limited Production Capacity:The baby formula industry has limited production capacity, making it difficult to quickly ramp up production to meet increased demand.

- Formula Concentration:The U.S. baby formula market is dominated by a few large manufacturers, creating a lack of competition and reducing the industry’s ability to respond quickly to shortages.

Addressing Bottlenecks through the Defense Production Act

The DPA aims to address these bottlenecks by:

- Prioritizing the Production of Ingredients:The DPA can be used to prioritize the production of key ingredients for baby formula, such as milk powder, vitamins, and minerals. This will ensure that manufacturers have access to the necessary ingredients to increase production.

- Increasing Production Capacity:The DPA can incentivize manufacturers to expand their production capacity, potentially through financial assistance or tax breaks. This would increase the overall supply of baby formula.

- Improving Supply Chain Efficiency:The DPA can help to improve the efficiency of the baby formula supply chain by streamlining transportation and distribution processes. This will ensure that formula reaches consumers more quickly.

Timeline for Impact of the Defense Production Act

The impact of the DPA on baby formula availability is expected to be gradual, with noticeable improvements in the coming months.

- Short-term (1-3 months):The DPA will likely lead to an increase in the production of key ingredients, which could start to alleviate the shortage within a few months. However, the full impact of the DPA will take longer to materialize.

- Medium-term (3-6 months):Increased production capacity and improved supply chain efficiency will start to have a more significant impact on baby formula availability, leading to a more stable supply.

- Long-term (6+ months):The DPA is expected to create a more resilient baby formula supply chain, reducing the likelihood of future shortages. However, it is important to note that the effectiveness of the DPA will depend on the government’s ability to effectively implement the program.

Implications for Manufacturers: Biden Invokes Defense Production Act To Require Manufacture Of Baby Formula Ingredients

The Defense Production Act (DPA) has significantly impacted baby formula manufacturers, presenting both challenges and opportunities. The act aims to prioritize the production of essential ingredients for baby formula, ensuring a steady supply for American families.

Challenges for Baby Formula Manufacturers

The DPA has imposed various challenges on baby formula manufacturers, primarily related to increased production demands and potential supply chain disruptions.

Biden’s invocation of the Defense Production Act to ramp up baby formula production is a stark reminder of the government’s role in ensuring essential needs are met. It’s a far cry from the rhetoric of some GOP candidates, who are embracing a brand of christian nationalism that prioritizes individual responsibility over collective action.

While the formula shortage highlights the need for government intervention, the rise of this divisive ideology underscores the importance of a robust public sphere that values empathy and cooperation, not just individual gain.

- Increased Production Demands:The DPA requires manufacturers to prioritize the production of baby formula ingredients, leading to increased production demands. Meeting these demands requires manufacturers to adjust their existing production lines and potentially invest in new equipment and facilities.

- Supply Chain Disruptions:The DPA’s focus on domestic production can disrupt existing supply chains, as manufacturers may need to source ingredients from new suppliers or adjust their logistics operations.

- Regulatory Compliance:The DPA introduces new regulations and compliance requirements for baby formula manufacturers, which can be time-consuming and resource-intensive.

Opportunities for Baby Formula Manufacturers, Biden invokes defense production act to require manufacture of baby formula ingredients

The DPA also presents opportunities for baby formula manufacturers, particularly in terms of market share and brand reputation.

- Increased Market Share:The DPA’s focus on domestic production could lead to increased market share for American baby formula manufacturers, as they become the primary suppliers for the US market.

- Enhanced Brand Reputation:By prioritizing the production of baby formula ingredients, manufacturers can strengthen their brand reputation and build trust with consumers.

- Government Support:The DPA provides financial and logistical support to manufacturers, which can help them overcome challenges and expand their operations.

Adapting Operations to Meet Increased Demand

Baby formula manufacturers are adapting their operations to meet the increased demand for their products.

- Expanding Production Capacity:Manufacturers are increasing production capacity by adding new production lines, extending existing shifts, and investing in new equipment.

- Optimizing Production Processes:Manufacturers are optimizing their production processes to improve efficiency and maximize output. This includes implementing lean manufacturing principles, automating tasks, and streamlining logistics operations.

- Prioritizing Ingredient Sourcing:Manufacturers are prioritizing the sourcing of essential ingredients, ensuring a consistent supply chain for critical components.

Impact of the Defense Production Act on Different Baby Formula Manufacturers

| Manufacturer | Impact |

|---|---|

| Abbott Laboratories | Abbott Laboratories, the largest baby formula manufacturer in the US, has been significantly impacted by the DPA. The company has been working to increase production capacity and secure ingredients, while also facing regulatory scrutiny. |

| Nestle | Nestle, another major baby formula manufacturer, has also been impacted by the DPA. The company has been working to increase production capacity and improve supply chain efficiency. |

| Perrigo | Perrigo, a smaller baby formula manufacturer, has seen a surge in demand for its products. The company has been working to expand production capacity and meet the needs of consumers. |

Government Oversight and Future Strategies

The Defense Production Act (DPA) invocation for baby formula ingredients necessitates robust government oversight to ensure its effective implementation and prevent future shortages. This involves monitoring the production and distribution of essential ingredients, addressing potential bottlenecks, and establishing long-term strategies for a resilient supply chain.

Government Agencies’ Role in Overseeing DPA Implementation

The DPA’s successful implementation relies heavily on the coordinated efforts of various government agencies. The Federal Trade Commission (FTC) and the Food and Drug Administration (FDA) play crucial roles in overseeing the production and distribution of baby formula ingredients. The FTC investigates any potential price gouging or unfair business practices, while the FDA ensures the safety and quality of the ingredients.

The Department of Health and Human Services (HHS) coordinates efforts to ensure the availability of baby formula, particularly for vulnerable populations. These agencies work together to monitor the progress of the DPA’s implementation, identify potential challenges, and take necessary corrective measures.

Long-Term Strategies for Preventing Future Baby Formula Shortages

To prevent future shortages, the government is exploring several long-term strategies, including:

- Diversifying the Supply Chain:Reducing reliance on a limited number of manufacturers and increasing the number of domestic producers can enhance the resilience of the supply chain. This can be achieved through incentivizing domestic production, streamlining regulatory processes, and providing financial assistance to new entrants.

- Building Strategic Reserves:Maintaining a strategic reserve of baby formula ingredients can provide a buffer against unforeseen disruptions. This reserve should be regularly replenished and managed to ensure its effectiveness in responding to emergencies.

- Enhancing Regulatory Oversight:Strengthening regulatory oversight of baby formula manufacturers can help prevent future shortages. This includes robust quality control measures, stricter enforcement of safety standards, and increased transparency in ingredient sourcing and production processes.

- Improving Communication and Coordination:Effective communication and coordination among government agencies, manufacturers, and retailers are crucial for ensuring a timely and efficient response to future shortages. Establishing clear communication channels and coordinating actions can streamline decision-making and resource allocation.

Government’s Plans for Ensuring the Long-Term Sustainability of the Baby Formula Supply Chain

The government aims to strengthen the baby formula supply chain through various initiatives:

- Supporting Domestic Production:The government is actively encouraging domestic production of baby formula by providing financial assistance, streamlining regulatory processes, and incentivizing investment in manufacturing facilities.

- Facilitating Importation:The government is working to facilitate the importation of baby formula from reliable sources to meet the demand, while ensuring adherence to safety and quality standards.

- Improving Distribution Networks:The government is exploring ways to enhance the distribution network, including optimizing logistics and ensuring efficient transportation to reach all consumers, particularly in underserved communities.

- Investing in Research and Development:The government is investing in research and development to explore alternative ingredients and production methods, enhancing the diversity and resilience of the baby formula supply chain.

Ending Remarks

The invocation of the Defense Production Act for baby formula production represents a significant step towards addressing the shortage, but it’s not a quick fix. The full impact of this action remains to be seen, but it underscores the importance of a robust and resilient baby formula supply chain.

The situation highlights the need for a multifaceted approach, including increased domestic production, streamlined regulations, and improved supply chain resilience, to ensure that families always have access to safe and nutritious baby formula.